Table of Contents

- Getting Started

Resistors

- Tube Sockets

- Capacitors

- Semiconductors

- Connectors

- Wiring Diagrams

- Checkout

- Enclosures

Resistors

The resistors are installed first on the board. Many of them are the smallest components used in this design and they can be difficult to install once the larger components, especially the tube sockets, have been installed. They are also the easiest to install, since they are relatively immune to damage from excessive soldering heat. I recommend installing the resistors in numerical order beginning with R1 and ending with R29. Some builders prefer to install all of the like valued resistors at the same time, going out of sequence. I find that this increases the probability of error, and doesn't save much time. I also recommend printing out the check list, and checking off each part as it is installed. Resistors have no polarity and may be installed in either direction. Some builders will take the time to face all the resistors in the same direction. I do not have the patience for that, but it is perfectly acceptable. Pictures are provided for all of the steps.

The question was asked by early build testers, why the resistors are installed on the top side of the board when using the inverted assembly method. The reason that this is done is to reduce the chance of error. There are more resistors than all other components combined. There is no silk screening on the back side of the board. It would be easy to get a resistor in the wrong holes, and since they are mostly small parts, inverted mounting is not needed. Once the resistors are mounted, the holes for the other parts are more obvious since there are fewer empty holes. There is no technical reason why the resistors couldn't be placed on the back side, and this could be done with the large ones if desired. I don't recommend this for first time builders.

The components were numbered according to their function in the design. Resistors R1 through R4 are part of the power supply. R10 through R19 are part of the right channel amplifier circuit, and R20 through R29 are part of the left channel amplifier circuit. For this reason there is no R5 through R9 on this board.

Five different physical sizes of resistors are used on this board. The physical size is related to the amount of power each resistor can dissipate. Each resistor is also available is varying tolerance values. This is the measure of how close the resistor is to its stated value.

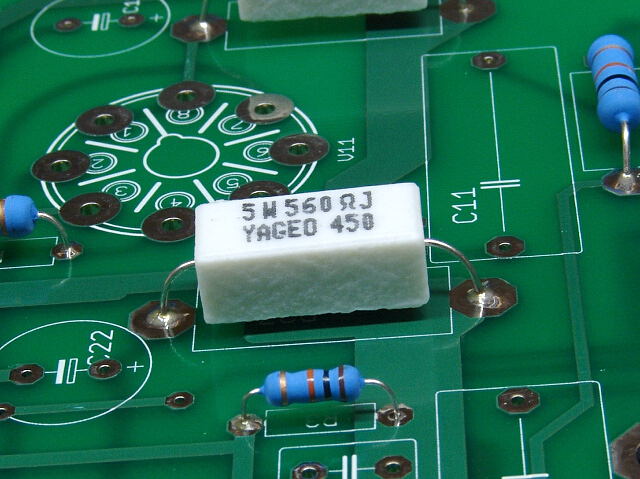

The largest are the 5 watt wire wound resistors used for R1, R17, and R27. These are usually white ceramic cased rectangular parts. They are shown in the photos below. It is possible for these to be round and come in a different color with black being the most common. These usually come in 5% and 10 % tolerance values. The resistance, power rating and tolerance is usually written on the case.

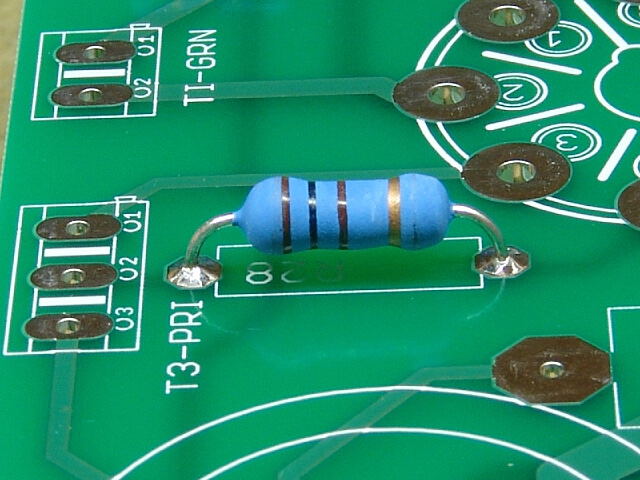

There are 1 watt, 2 watt, and 3 watt carbon film resistors used on this board. A 3 watt resistor is shown below in the R2 picture. R3 is a 1 watt resistor, and R4 is a 2 watt resistor. These are usually blue, grey, or tan in color with 4 color bands to mark the resistance and tolerance value. The power rating is determined by the physical size, and no standard sizes exist.

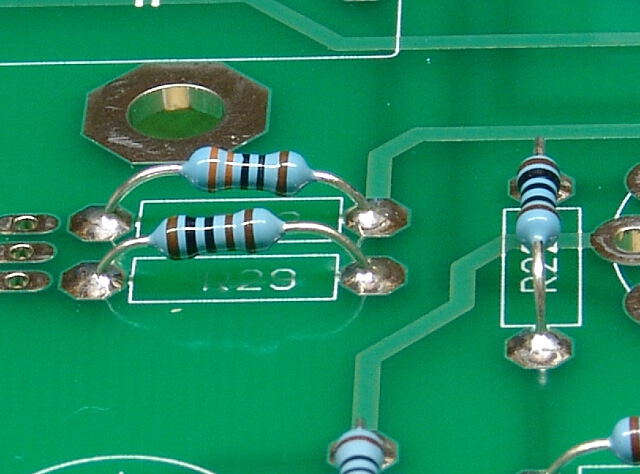

There are also many smaller sized resistors used on this board. These may be 5% or 1% in tolerance, and 1/4 or 1/2 watt power rating. Any of the 4 possible combinations may be used on this board. They may be marked in two possible ways. The 5% resistors are marked with 3 color bands for the resistance value, and a gold band to designate the 5% tolerance value (4 colored bands total). The 1% resistors have 4 color bands for the value, and a brown band to designate the 1% tolerance value (5 bands total).

Familiarize yourself with the different sizes of resistors before installing any of them. In this design there are different sized resistors with the same resistance value (R2 and R4 are both 150K but different size, this was dictated by the PC board layout). It would be a good idea to identify the resistor used in each component location, and verify its fitment in the PC board before beginning any assembly. It may be helpful to pre-bend the leads of all of the resistors and sort them into a small tray for easy identification during board assembly. Old ice cube trays are useful for this.

If you are going to use the inverted assembly method, it is important that all of the resistors are close to (but not touching) the PC board. When the PC board is mounted to the chassis top plate, there will be about 1/2 inch from the board to the metal plate. There must be sufficient clearance between the components and the grounded chassis plate. Even though the resistors (and other components) have an insulating coating, they should not be in contact with ANY conductive surface, or other components. This is also true for conventional point to point construction. Over time, heat and vibration will eventually break down the insulating coating. If any of your particular resistors are too big for this, mount them on the back side of the PC board.

Begin installing the resistors using the technique shown in the Getting Started page.

R1 is only used if a power supply choke is NOT being used. If you are using R1, insert and solder it as shown. Clip the excess leads from the part after soldering. If you are not using R1, leave these holes empty, no component is installed in the location for R1. If you are still undecided, leave it out. It can be easily added later.

R1 is only used if a power supply choke is NOT being used. If you are using R1, insert and solder it as shown. Clip the excess leads from the part after soldering. If you are not using R1, leave these holes empty, no component is installed in the location for R1. If you are still undecided, leave it out. It can be easily added later.

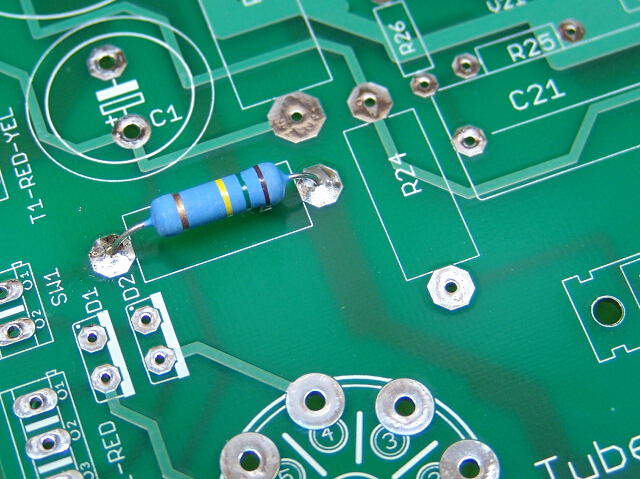

Next insert and solder R2.

Next insert and solder R2.

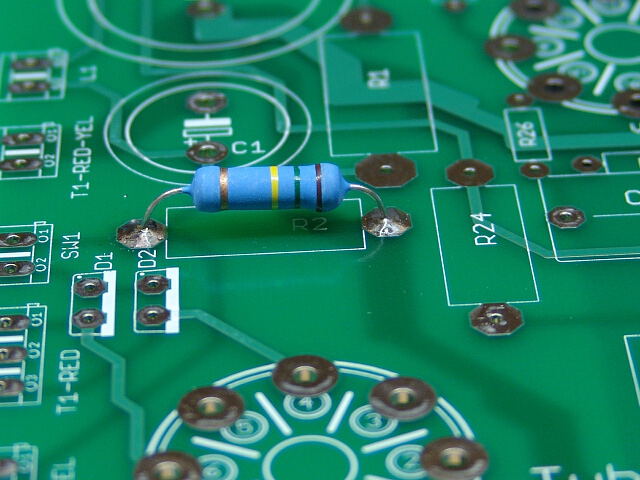

R2, showing proper component height. It is especially important not to space the resistors too high off the PC board if the inverted assembly option is used. R1 is not used in this board.

R2, showing proper component height. It is especially important not to space the resistors too high off the PC board if the inverted assembly option is used. R1 is not used in this board.

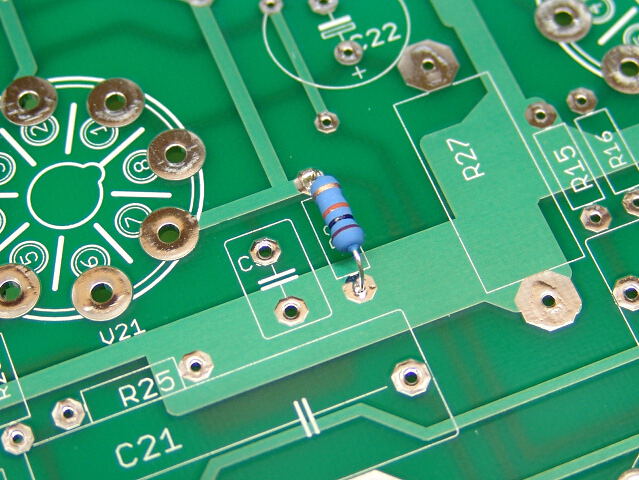

Next insert and solder R3.

Next insert and solder R3.

This is a side view of R3.

This is a side view of R3.

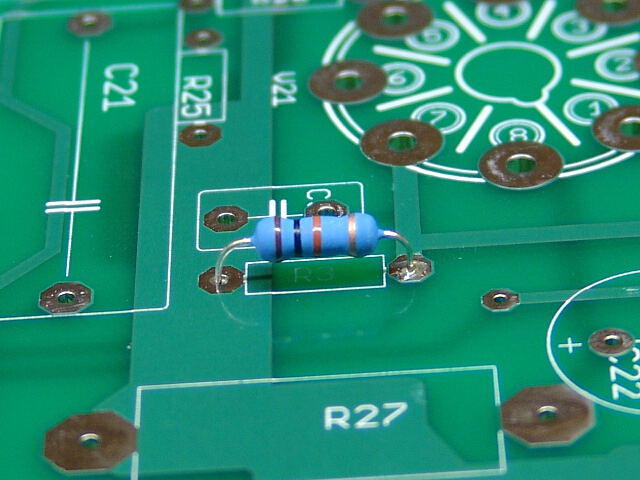

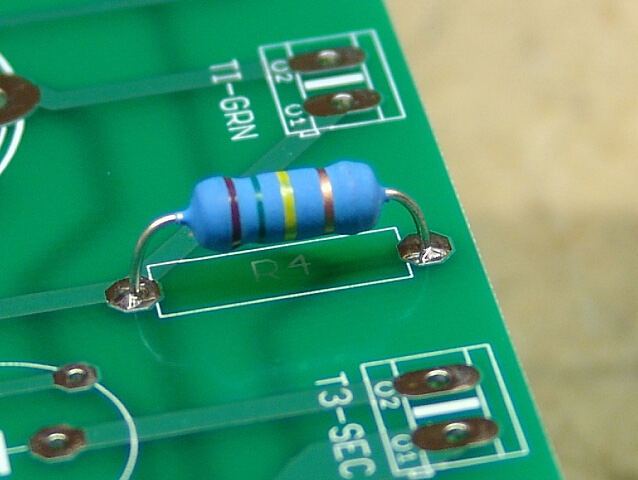

Next insert and solder R4.

Next insert and solder R4.

R3 and R4, side view.

R3 and R4, side view.

There is no R5 through R9 in this design. The next resistor is R10.

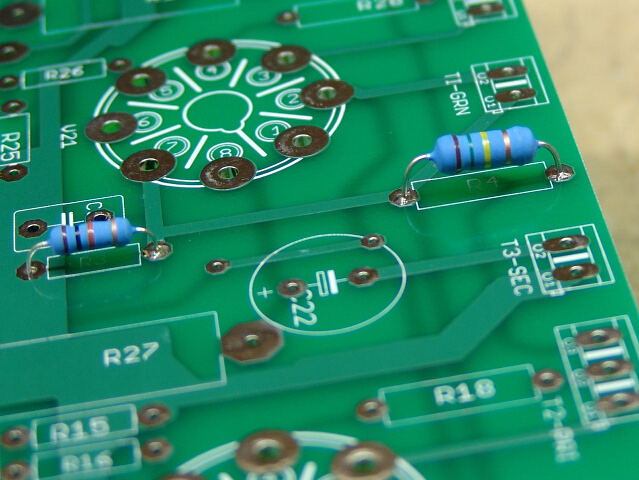

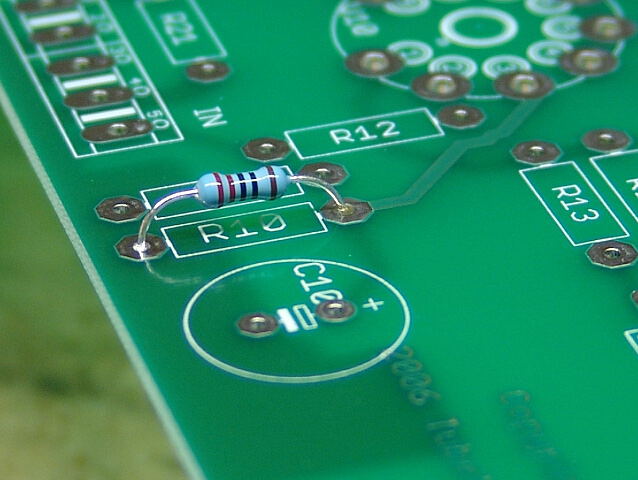

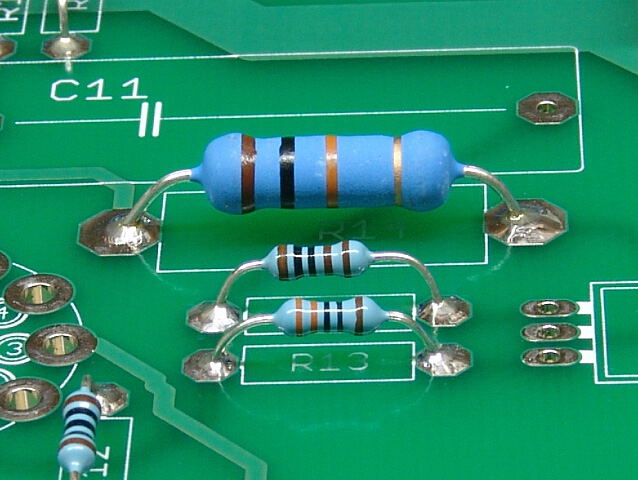

Install R10 as shown. A 1% metal film resistor is shown here.

Install R10 as shown. A 1% metal film resistor is shown here.

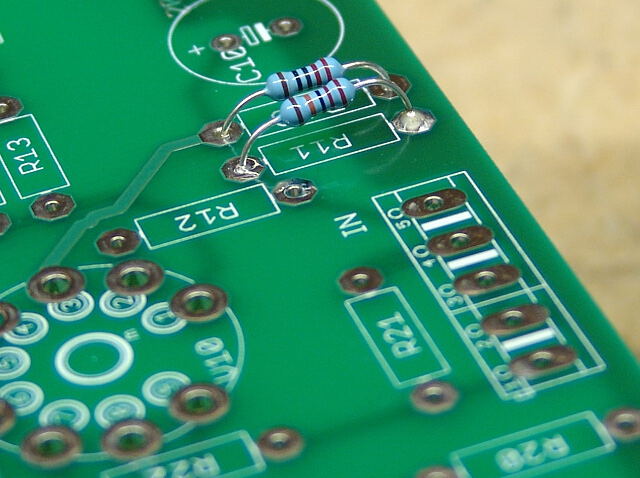

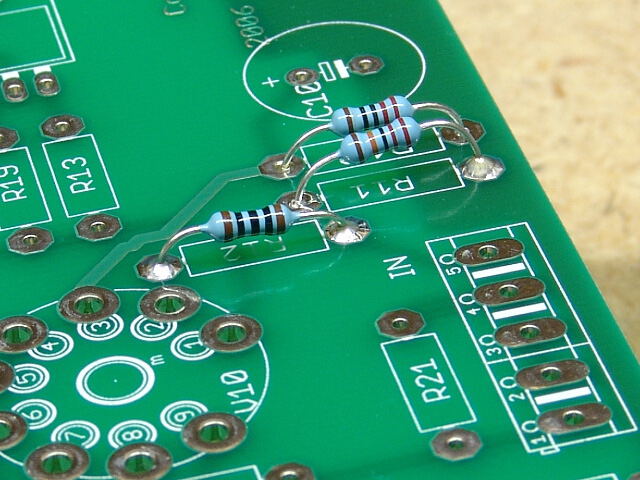

Insert and solder R11. It goes right next to R10 (shown in background).

Insert and solder R11. It goes right next to R10 (shown in background).

Insert and solder R12.

Insert and solder R12.

Insert and solder R13.

Insert and solder R13.

Insert and solder R14.

Insert and solder R14.

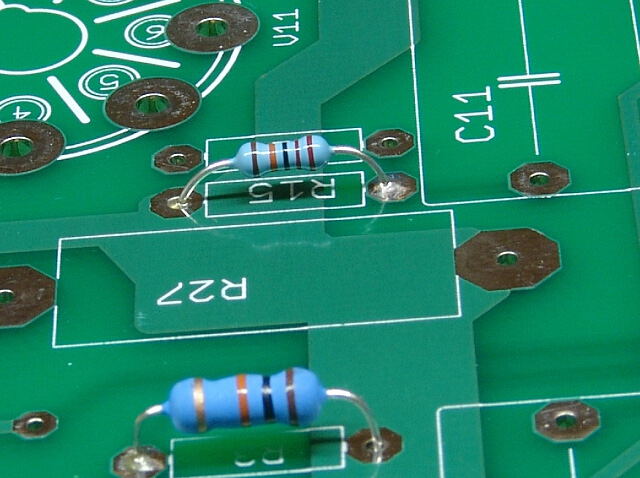

Insert and solder R15.

Insert and solder R15.

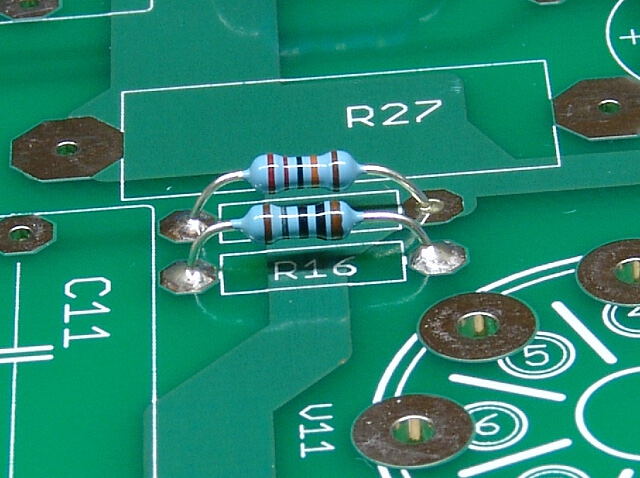

Insert and solder R16. R15 is directly behind it in this photo.

Insert and solder R16. R15 is directly behind it in this photo.

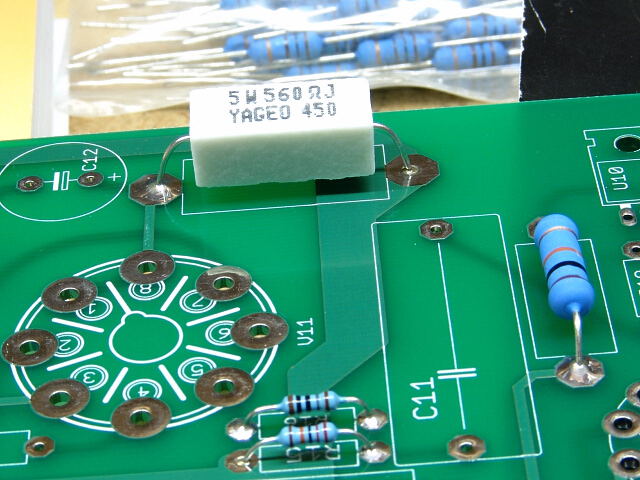

Insert and solder R17. It is a 5 watt ceramic wire wound resistor. Allow some space between the resistor and the PC board (about 1/8 inch or 3 mm), but do not place it any higher if you intend to use inverted assembly. If you are using conventional assembly, it is not critical.

Insert and solder R17. It is a 5 watt ceramic wire wound resistor. Allow some space between the resistor and the PC board (about 1/8 inch or 3 mm), but do not place it any higher if you intend to use inverted assembly. If you are using conventional assembly, it is not critical.

This is a photo of R17 taken from the edge of the board. R14 is visible to the left, R16 and R15 are above R17, and R3 is above them. R4 is to the left of R3. Your board should look like this one at this time.

This is a photo of R17 taken from the edge of the board. R14 is visible to the left, R16 and R15 are above R17, and R3 is above them. R4 is to the left of R3. Your board should look like this one at this time.

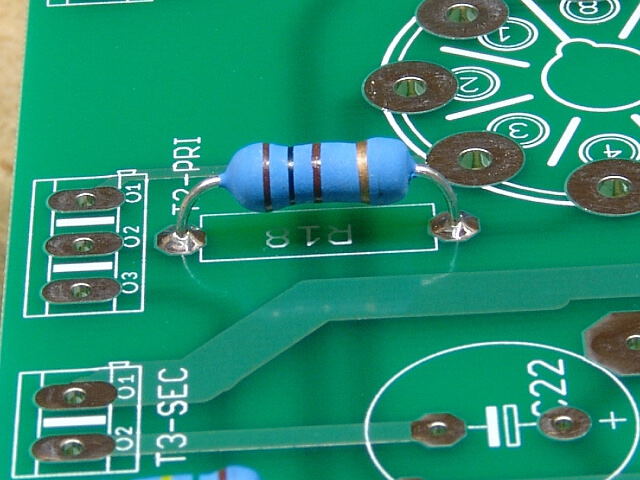

Solder R18 in place.

Solder R18 in place.

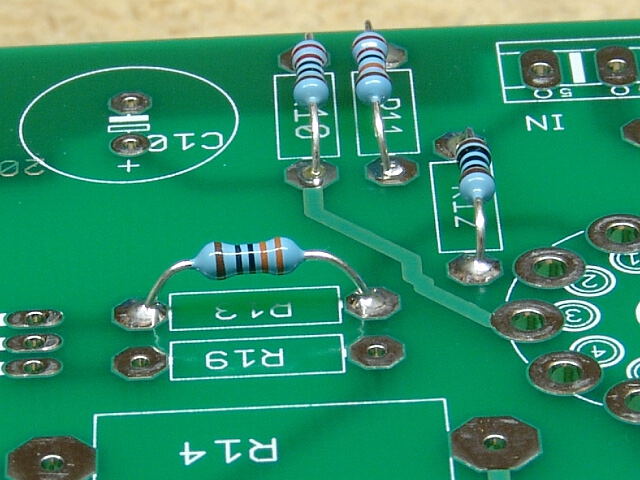

Insert and solder R19, it installs in between R13 and R14.

Insert and solder R19, it installs in between R13 and R14.

Insert and solder R20.

Insert and solder R20.

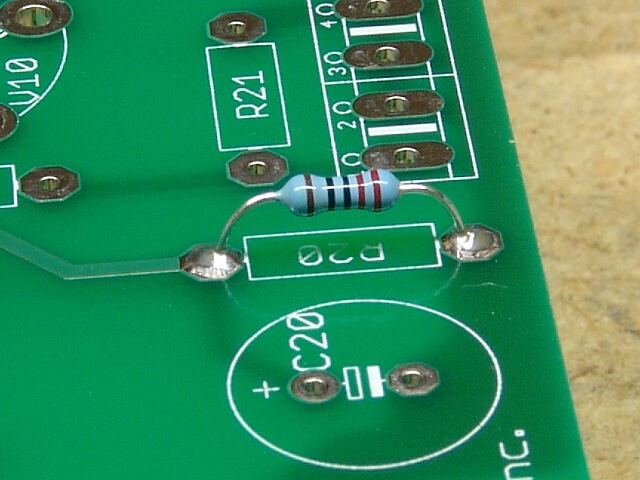

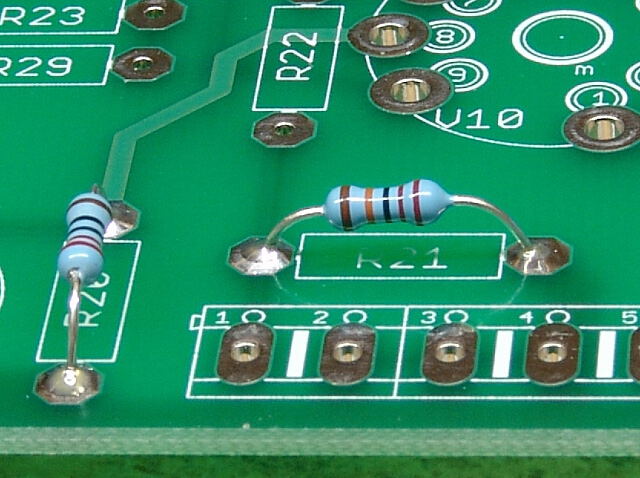

Insert and solder R21.

Insert and solder R21.

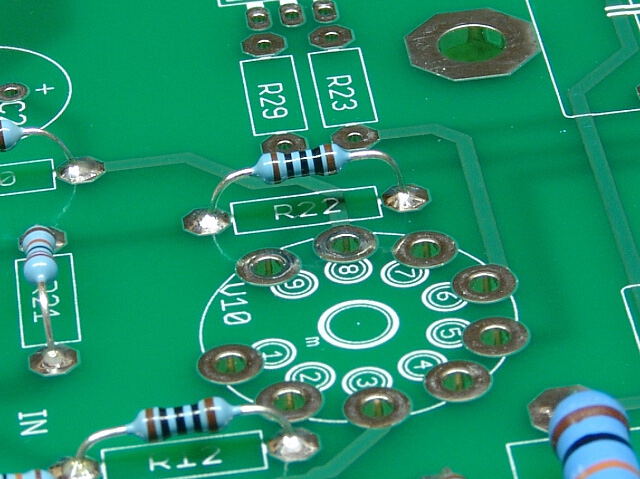

Insert and solder R22.

Insert and solder R22.

Insert and solder R23.

Insert and solder R23.

Insert and solder R24.

Insert and solder R24.

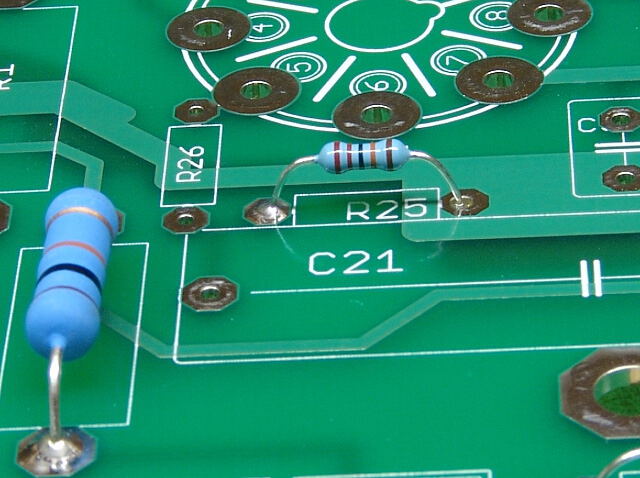

Insert and solder R25.

Insert and solder R25.

Insert and solder R26.

Insert and solder R26.

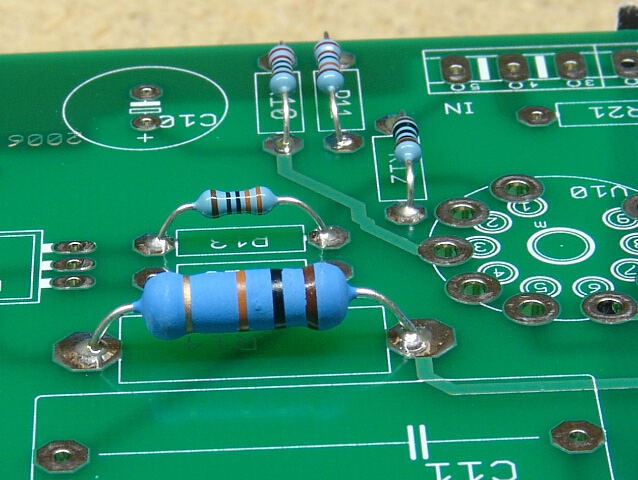

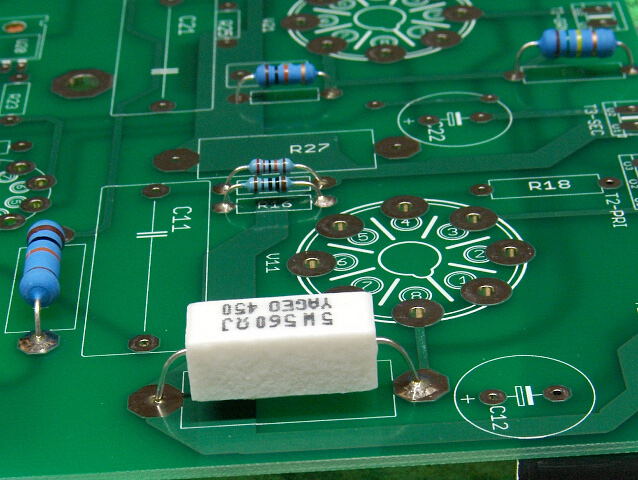

Insert and solder R27. It is a 5 watt ceramic wire wound resistor. Allow some space between the resistor and the PC board (about 1/8 inch or 3 mm), but do not place it any higher if you intend to use inverted assembly. If you are using conventional assembly, it is not critical.

Insert and solder R27. It is a 5 watt ceramic wire wound resistor. Allow some space between the resistor and the PC board (about 1/8 inch or 3 mm), but do not place it any higher if you intend to use inverted assembly. If you are using conventional assembly, it is not critical.

Insert and solder R28.

Insert and solder R28.

Insert and solder R29.

Insert and solder R29.

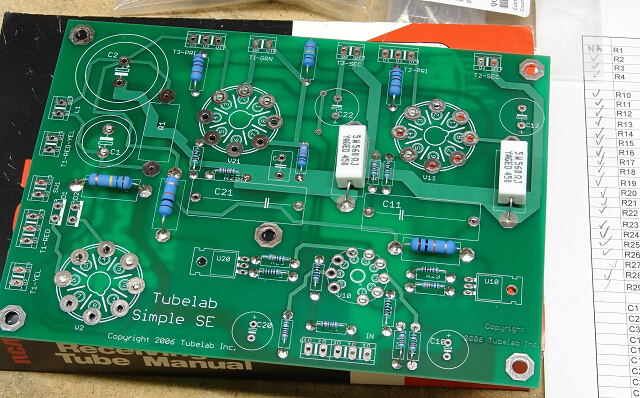

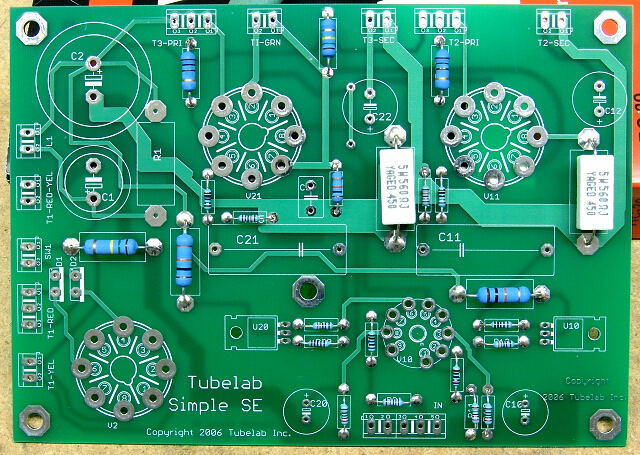

At this point all of the resistors are installed. Verify that you have installed them all, and all have been checked off on the parts list.

At this point all of the resistors are installed. Verify that you have installed them all, and all have been checked off on the parts list.

Another view of this board. This board does not use R1, so it is not present. If your application uses R1 there should be a large white resistor similar to R17 and R27 in the R1 location.

Another view of this board. This board does not use R1, so it is not present. If your application uses R1 there should be a large white resistor similar to R17 and R27 in the R1 location.

You are now done with the resistors. Please check over your board. Your board should look like this at this point. Your parts may look different than these, but there should be parts in all of these places, and none in any other places. A high resolution version of this photo is included on the CD in case you need to see the details of a single part.

If your board agrees with the photo, proceed to the Tube Sockets page.